What is particle simulation software?

Particle simulation software Particleworks is a mesh-less approach to CFD that discretizes the fluid domain automatically with particles.

What is Particleworks?

Particleworks is a mesh-free CFD software utilizing the Moving Particle Simulation method. It excels in simulating liquid and multi-phase flows, offering a straightforward process for complex geometries with moving parts.

What is Moving Particle Simulation?

Particleworks is a mesh-free CFD software utilizing the Moving Particle Simulation method. It excels in simulating liquid and multi-phase flows, offering a straightforward process for complex geometries with moving parts.

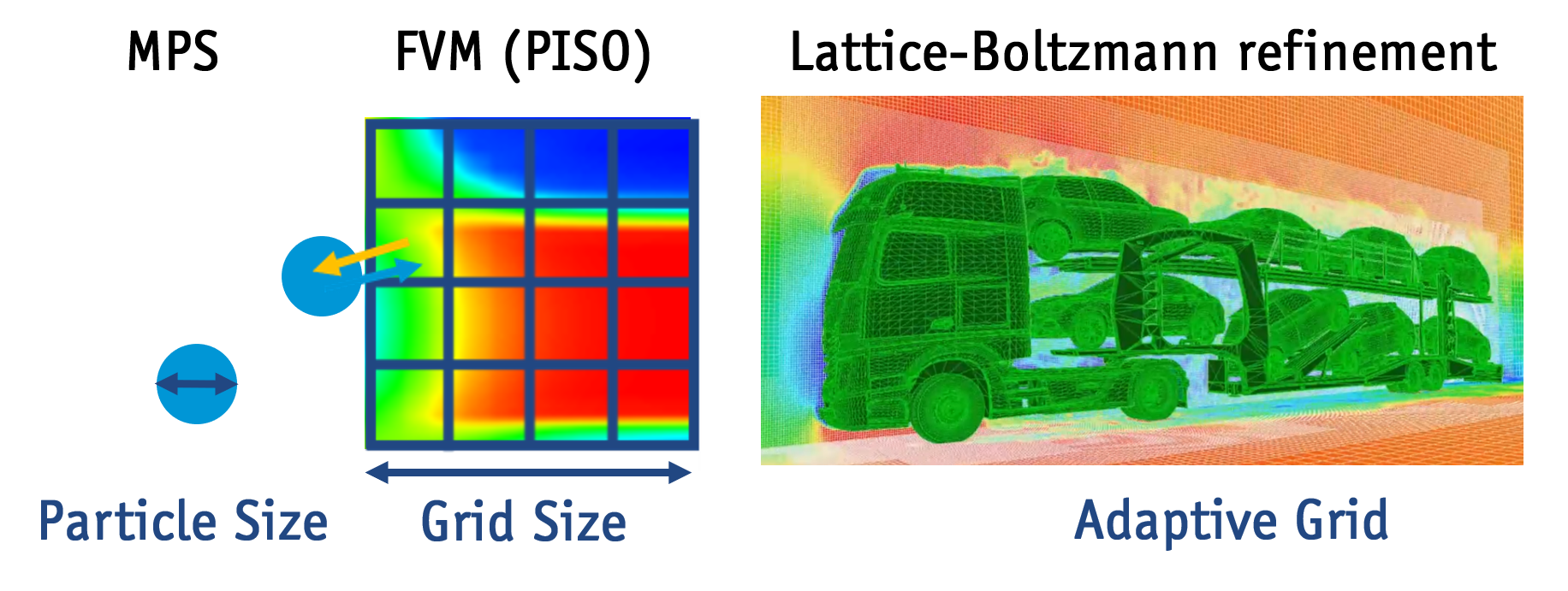

What are the differences between mesh-based and mesh-less CFD?

Mesh-based CFD relies on a structured grid for fluid simulations, involving complex mesh generation and Eulerian methods. In contrast, mesh-less CFD, like Moving Particle Simulation (MPS), employs particles for fluid discretization, offering adaptability to complex geometries and Lagrangian tracking. Mesh-less CFD, being computationally efficient and suitable for simulations with moving parts, presents a streamlined approach for fluid dynamics compared to traditional mesh-based methods.

What are examples of particle simulation?

Particleworks is applied across automotive, aerospace, consumer goods, power generation, and the food and beverage (F&B) industry. Its main applications include oil splashing, lubrication, engine cooling, water interaction analysis, water turbines, and handling highly viscous flows.

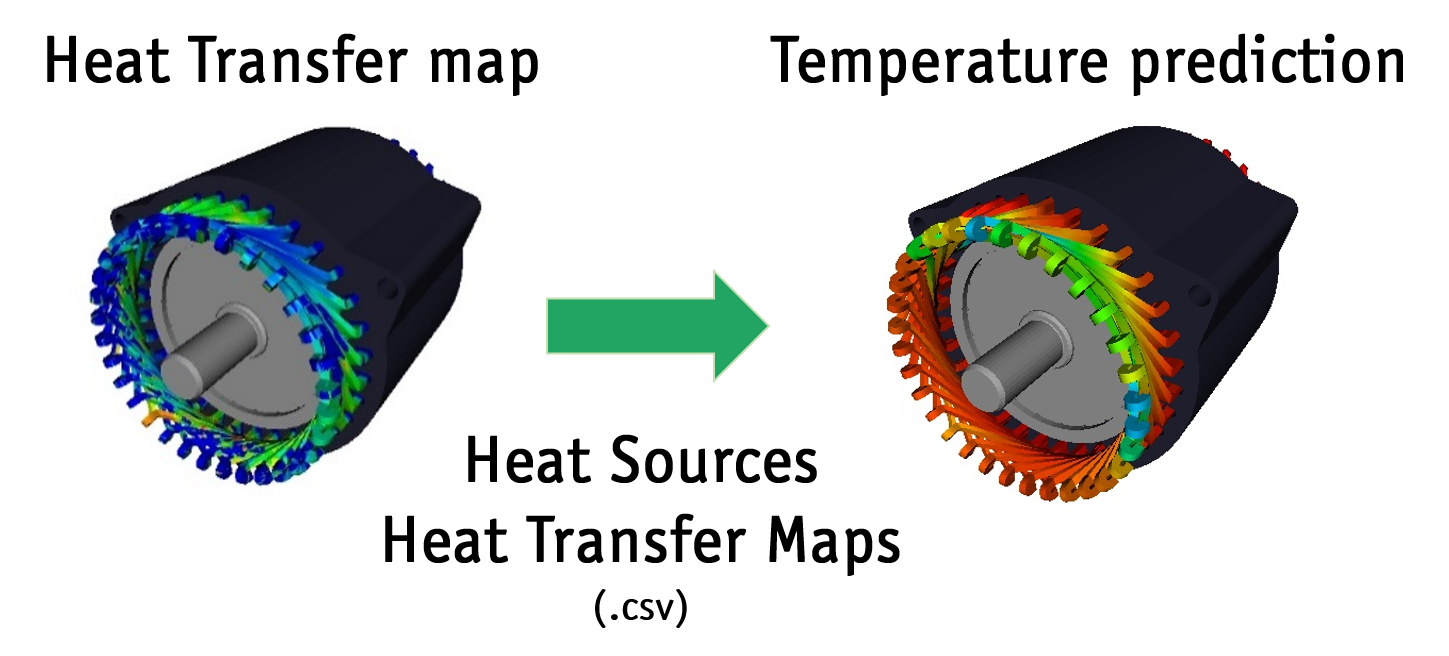

Can particle simulation predict temperatures?

Particleworks excels in heat transfer simulations, with an integrated solver for conjugate heat transfer between fluids and solids. This eliminates the need for solid particle generation, making the prediction of fluid flow, heat transfer coefficient, and temperature distribution more efficient.

What features are available in Particleworks?

Particleworks has a dedicated Python API, enabling users to automate the entire simulation process. The interface includes features like scene comparison, object copying, periodic movements, task management, live plots, and multi-view options, enhancing automation, time savings, and user experience.

What software can be coupled with Particleworks?

Particleworks supports co-simulation via the functional mock-up interface, dynamically interacting with third-party software. Notable partnerships include co-simulation RecurDyn or Adams for wading simulations. Moreover, Particleworks is integrated in Ansys Workbench (Mechanical and Fluent) as well as with Romax, to easily streamline the simulation workflow.

What are the differences between Smoothed Particle Hydrodynamics and Moving Particle Simulation?

Smoothed Particle Hydrodynamics (SPH) and Moving Particle Semi-implicit (MPS) are two particle methods used in fluid dynamics simulation. SPH is a method used for simulating the mechanics of continuum media. It is a meshfree Lagrangian method, and the resolution of the method can easily be adjusted. This method is used in various fields, like astrophysics, ballistics, volcanology, and oceanography. On the other hand, MPS is also a meshfree particle method. It was developed to simulate free-surface flows. The method is based on the idea of replacing the pressure terms in the Navier-Stokes equations with a semi-implicit form, which allows for larger time steps and therefore more efficient computation. Discover more...