CLUTCHES and BRAKES

Clutches and brakes design face a critical challenge: increasing performance demands. As industries demand more efficient and reliable transmission systems, traditional designs fall short. Enter the innovative solution: advanced materials and smart systems. The development of clutches and brakes presents several challenges. Managing heat generation and wear is crucial to prevent failure and ensure longevity: identification of wear patterns is key to prevent system failure2. Other challenges include managing the complexity of the products and systems, increasing development efforts, demands for a high level of innovation, focus on core competencies and collaborations, flexibility and ability to respond quickly, development of new markets, and enhanced pressure on the market because of prices.

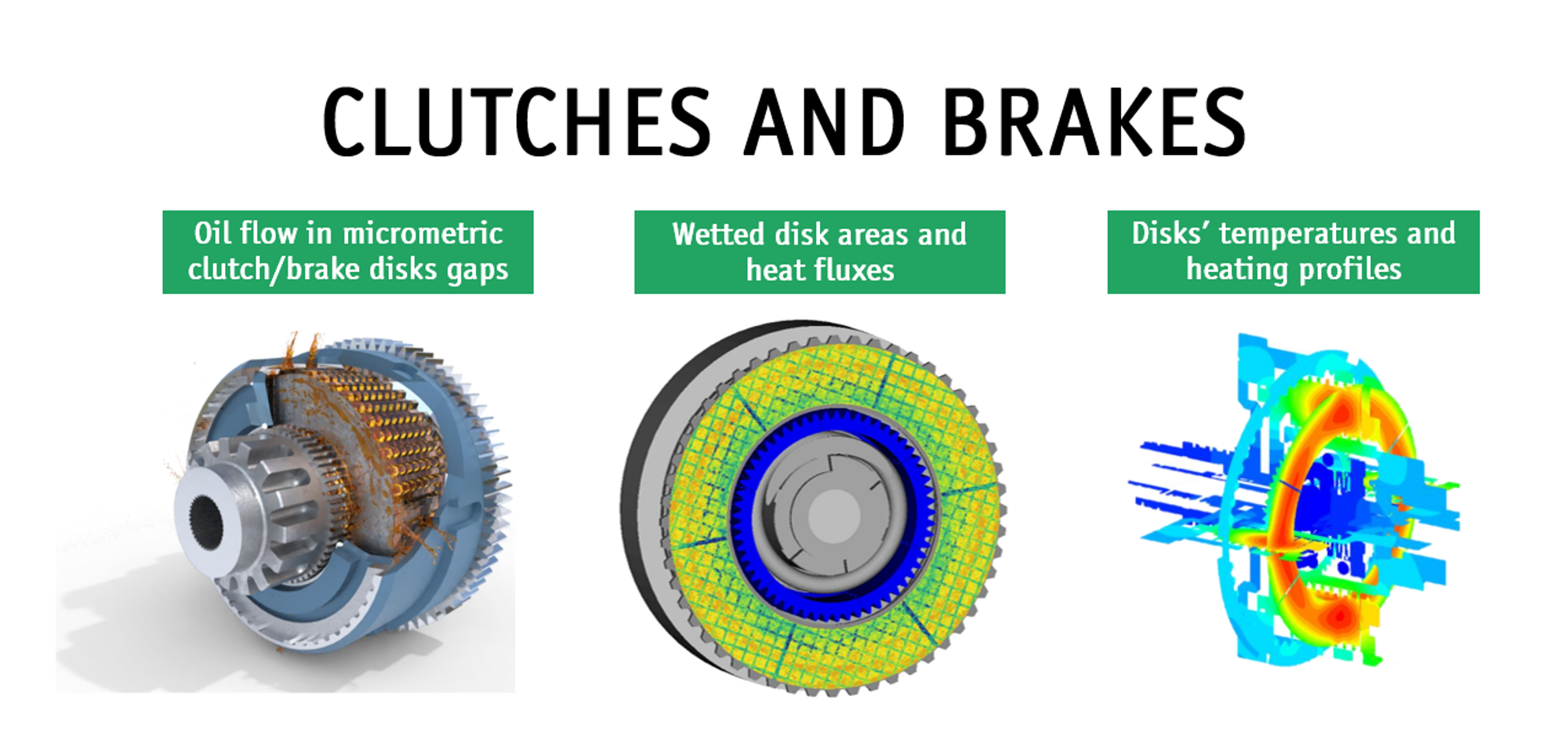

Particleworks creates digital prototypes of clutches and brakes:

- Oil flow between clutch plates

- Flow distribution in distributing channels

- Heat Transfer Coefficient on plates

- Influence of working condition

- Temperature prediction in clutch and brake disks