Massimo Galbiati and Stefano Odorizzi

Welcoming speech Particleworks Experience 2023

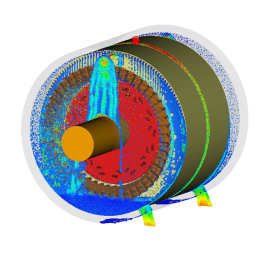

DUCATI CORSE | Speaker Gaspare Argento

Estimation of cycle average convective heat transfer coefficient on the underside of a racing piston taking into account oil flowing from conrod and main bearings

Oil jets are widely used in high performance and racing engines to prevent the piston from overheating and protect the engine from serious damage. The oil flowing across the underside of the piston helps cooling off the component thanks to the heat transferred to the oil. However, this is not the only contribution.

The oil flowing out from conrod and main bearings has a far from negligible influence on the resulting heat transfer performance. The main goal of this work was to model all the aspects playing a role on the piston cooling, considering not only oil jets but also the bearings contribution. A comparison based on the cycle average convective heat transfer coefficient values on the underside of the piston between this case and a jets only scenario is provided.

All simulations were performed using the commercial mesh-free CFD software Particleworks.

CARRARO | Speaker Massimo Bettio

Comparison between experimental measurements and numerical estimations of temperatures on a transfer box for an electric compact wheel loader

The high rotational speeds of e-motors and the consequent increase in power losses and temperatures are among the most challenging topics related to electrification in the field of power transmission systems, especially for the off-highway market. This paper presents the comparison between numerical estimates and experimental temperature measurements on a transfer box for an electric compact wheel loader. Steady-state numerical simulations were carried out using Ansys Thermal FE Solver in one case, and Particleworks CHT in the other to obtain the numerical estimates.

Both simulations received as input the thermal power generated by gears, bearings, and seals (estimated from analytical formulations in the literature), and the heat transfer coefficient (HTC) map on the inner surface of the housing, calculated from a previous Particleworks analysis taking into account the effective oil distribution for the speeds investigated during the experimental tests.

The numerically estimated temperatures of the analyzed positions are in agreement with the experimental results.

The workflow presented has proven invaluable in supporting design decisions early in the development process, with the aim of shortening the experimental validation phase by reducing the number of prototypes and tests.

POLESTAR | Speaker Gabriele Puccio

Development of Direct Oil Cooling Solutions for E-mobility Traction Motors Part I: Stator Cooling Concept

This paper presents different oil cooling configurations with possibilities for use in electric machines designed and developed for e-mobility applications.

The focus in this part of the paper is on stator cooling. Different cooling solutions based on cooling channels in the lamination, wind-cap, and sleeve are presented and discussed. The proposed configurations are evaluated using transient fluid flow simulations and a comparison of the results is presented. In addition, the simulation results are evaluated and verified using measurements on a 3D-printed prototype.

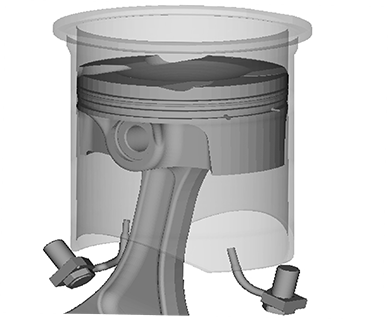

POWERTECH ENGINEERING | Speaker Andrea Bianco

Piston Cooling Jets for High-Performance Engines: development of a simulation strategy based on MPS and CHT

Within the context of engine development, the pursuit of increased specific power output continues to pose several challenges, one of the most significant of which is to limit thermal stresses in pistons.

In this context, the present work exploits the potential of Moving Particle Simulation (MPS) to develop and validate a methodology to assess piston cooling jets in high-performance engines. The initial simulations involved impinging jets and were validated against existing experimental data of reference cases. Thereafter, the validated simulation setup was used to analyse the piston cooling jets in an innovative piston design for a high-performance engine. Conjugate heat transfer simulations demonstrated that the piston performed well compared to available data for high-performance engines.

The validated simulation methodology was significantly faster than traditional finite-volume-based simulations while still allowing realistic assessment of piston thermal performance.

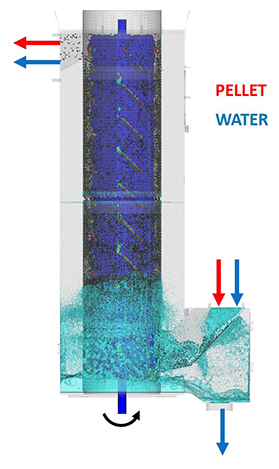

GAMMA MECCANICA | Speaker Lorenzo Iorio

Preliminary design optimization study of a centrifugal machine for a plastic recycling system

The plastic recycling sector is becoming very important day by day in order to reduce the impact of pollution on the natural environment, which is one of the hottest topics of recent years.

It is well known that plastic materials are quite difficult to handle due to the particular viscoelastic phenomena that occur during recycling. For this reason, it is clear that the design and optimization of recycling plants must be aided by the introduction of advanced numerical simulation algorithms to simulate the flow of liquid and solid particles.

This paper presents a preliminary optimization study of a centrifugal machine to dry plastic. The simulation model enabled the motion of the water and plastic particles inside the centrifuge to be described.

The velocity and distribution results of the particles inside the centrifuge suggested a different design solution which aims to combine all the advantages of the project solutions simulated so far.

PUNCH TORINO | Speakers Marco Pini and Antonella Calamiello

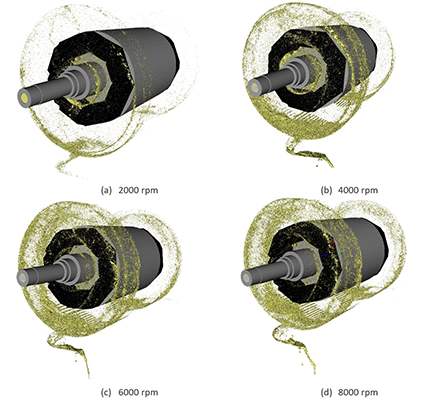

Validated e-axle gearbox analysis model and methodology for assessing lubrication efficiency

We will present an activity undertaken to define and validate an analysis setup and methodology in Particleworks for a gearbox model; a good correlation was achieved both in terms of qualitative oil distribution and in trends of torque values for different working conditions. The SW was able to correctly capture the oil distribution even in critical channels with an acceptable computational cost.

Analysis and test results were compared for different working conditions. The validated methodology is now used to guide different design activities, screen architecture activities, and optimize oil levels.

RIMAC TECHNOLOGY | Speakers Ivan Krajinović and Stanislav Sviderek

Rimac Technology - always going the extra mile

An introduction to the activities and capabilities of Rimac Group, Bugatti Rimac, and Rimac Technology will be given.

In addition, the presentation will show simulation activities within the Simulation department of Rimac Technology.

Finally, the introduction of ParticleWorks in standard simulation techniques will be shown together with representative examples of the problems addressed.

SKF INDUSTRIE | Speaker Fabrizio Mandrile

A novel numerical analysis method for predicting non-Newtonian lubricant (grease) distribution in ball bearings

Authors: Mehul Pandya, Pietro Tesini, Fabio Bogliacino and Fabrizio Mandrile | SKF

Grease is a viscoelastic fluid and the most common lubricant for rolling bearings. During the churning phase (initial phase) of bearing operation, most of the grease is set in various locations called grease reservoirs. The grease reservoirs supply lubricant to the bearing contacts by bleeding.

Since the distribution of the grease reservoirs is crucial for optimal bearing lubrication, the design of bearing components, e.g. the cage, aims for optimal grease distribution after the churning phase. It is difficult to observe the effect of component design on grease distribution through real-life experiments, so MPS simulations are performed here. This method can help determine the factors influencing the grease distribution within the bearing after churning, with the ultimate goal of improving lubrication.

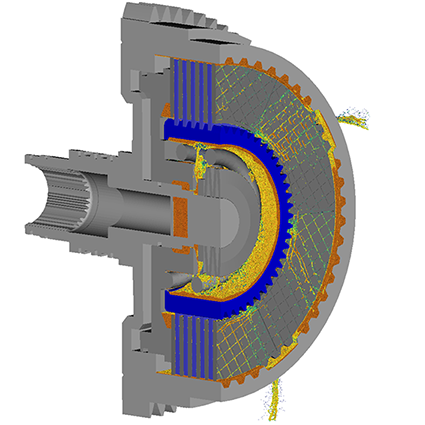

EnginSoft | Speaker Gianluca Parma

Multi-plate clutch for agricultural applications: a novel method for oil flow and heat transfer analysis

The multi-plate clutch is a specific type of clutch for transmitting high torque and it is widely used in agricultural machinery, trucks, racing cars, etc. A multi-plate clutch is composed of several friction plates that engage to reduce slipping effects when plates are packed to transmit torque.

Although this type of device is mechanically efficient, the multi-plate configuration implies a significant increase in heat generation, which can be dissipated by oil injection.

In this context, Moving Particle Simulation can play an important role in the design and optimization of oil injection and its distribution in the clutch.

This presentation describes the simulation method applied to model both the entire clutch and the oil flow in the small gaps between the plates simultaneously. The distribution of oil flow and heat transfer coefficient in both open and closed clutch configurations is presented and explained, along with accompanying illustrations.

CHALMERS UNIVERSITY | Speaker Luca Boscaglia

Direct Oil-Cooled Electrically Excited Synchronous Machine

Electrically Excited Synchronous Machines (EESMs) represent a convenient alternative to the widely used Permanent Magnet Synchronous Machines (PMSMs) since they do not need magnets and have higher efficiency at high speed.

The magnets are replaced with hundreds of active rotor conductors that pose a significant challenge from the thermal point of view, especially at design phase when no measurements can be executed. In this paper, a direct oil-cooled 200 kW EESM is considered and modeled in Particleworks to design and optimize the cooling system for both rotor and stator.

TREMEC | Mattia Porchetta

TREMEC - Particleworks user experience

This presentation highlights the use of Particleworks software in oil management activities conducted by TREMEC. The focus is on two test cases, namely the suction issue on the TR9070 gearbox and oil expulsion on the TR9080 gearbox. Both cases are supported by experimental data to demonstrate the accuracy and effectiveness of the software in predicting oil motion in gearboxes. The results indicate that Particleworks is a valuable tool for predicting oil behavior and enhancing oil management activities in the automotive industry. The findings of this study could contribute to the development of more efficient and reliable gearboxes.