The use cases will span various topics across different industrial sectors. The speakers will provide insights into cutting-edge applications of meshless CFD and elaborate on how their companies leverage Particleworks digital models for tangible benefits.

Program

8.00 – 8.30

COFFEE

8.30 – 8.45

WELCOME

8.45 – 9.30

Prometech Software | Takuya Natsume

An overview of the new features of Pw8.2 and Gw3.2

This presentation will introduce the latest versions of our software, Particleworks 8.2 and Granuleworks 3.2.

These updated versions feature significant improvements in the simulation of multi-phase flow and thermal coupling, enabling the simulation of complex phenomena across a wide range of applications. Additionally, we will present our latest case study from Japan.

The presentation provides insights for solving technical challenges and exploring new applications of Particleworks and Granuleworks.

9.30 – 10.00

SADEN Gmbh | Dr. Patrick Neuenfeldt

Approach to determine quantitatively correct load-independent power losses inside turbo gearboxes by flow simulation

The mechanical design of turbo gearboxes is now well understood, primarily due to decades of research by universities and the FVA. Key focus areas included geometry, lubrication, and power loss calculations, especially for high circumferential speeds. Test rigs like the FZG no-load rig were essential for identifying cause-effect relationships. Power losses mainly stem from windage, acceleration, and compression, which are hard to separate in real gearboxes. Since most research was based on similar setups, adaptations were necessary for other gearbox types. A universally valid method for calculating losses does not yet exist. To address this, SADEN GmbH uses Finite Volume Method (FVM) for air and Moving Particle Simulation (MPS) for oil to accuaretly calculate load-independent losses caused by air and oil. Validation in cooperation with TGSK showed only 5% deviation from experimental results over a wide range of parameters.

2013 to 2016 | Bachelor of Engineering, Mechanical Engineering, University of Applied Science Offenburg, Thesis: Numerical investigation of the three-dimensional, frictional near-sonic flow around filaments

2016 to 2018 |

Master of Science, Mechanical Engineering, University of Applied Science Offenburg, Thesis: Numerical simulation of the performance map of a trans

sonic high-performance radial compressor

07/2018 to 06/2022 |

Research associate at wbk Institute of Production Science at KIT, Karlsruhe Institute of Technology

Doctorade: Modeling of stream finishing for prediction of material removal and surface topography on complex geometries

07/2022 till now |

Founder and Managing Director SADEN GmbH

10.00 – 10.30

TOTAL ENERGIES | Hakim El-Bahi - Jonathan Raisin and Gianluca Parma (EnginSoft)

Simulation of lubricant aeration: model development and validation for two different lubricants

Lubricant aeration is an undesirable phenomenon that occurs in engines and transmission systems and can affect powertrain performance. Aeration can lead to increased power loss, reduced lubrication and cooling, accelerated lubricant ageing and can affect the efficiency of hydraulic components.

While lubricant chemistry plays a role, the fluid dynamics involved can be analysed using Computational Fluid Dynamics (CFD). Particleworks meshless CFD software includes a dedicated model for predicting air entrainment in lubricants. This allows the simulation of bubble formation, transport, coalescence and extinction.

In a joint effort, TotalEnergies and EnginSoft have developed two different Particleworks models to investigate the applicability of the Particleworks aeration model to real-world conditions.

The first model replicates TotalEnergies single-gear setup used to measure lubricant aeration. This model is used to fine-tune the aeration model parameters for different lubricants under a specific speed condition. This parameter tuning is essential because the chemical properties of the lubricant, such as the inclusion of deaerating additives, cannot be entered directly into the CFD models.

These optimised settings are then applied to a second and full gearbox model with two FZG gears to compare the aeration characteristics at different speeds and for two different lubricants. FZG gearbox is a reference test in the Electric Vehicle industry that is usually carried out to assess the lubricant performance.

The results obtained from the Particleworks models are compared with experimental data. This comparison focuses on oil aeration indicators including the extent of air generation, its volume fraction and bubble size distribution. The results indicate that once the model parameters are appropriately set for a particular setup, the model can effectively compare the aeration behaviour of different lubricants over a range of speeds and predict the aeration performance in a full gearbox.

10.30 – 11.15

BREAK

11.15 – 11.45

WITTENSTEIN | Michael Keller

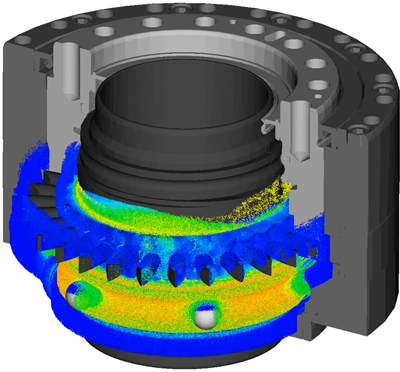

Insights into the lubrication of a Galaxie gearbox

The Galaxie gearbox is a new type of gearbox. The functional principle is based on numerous teeth that can be moved individually in a radial direction. They are driven by a central shaft to mesh with a ring gear. Due to the time-synchronised multiple engagement of the single teeth, the Galaxie gearbox combines maximum power density with high torsional stiffness - even during reversal rotation, which allows good controllability over the whole operation cycle. Typical areas of application are machine tools and production machines with high demands on precision and positioning accuracy.

The splash lubrication is a key element that guarantees the functionality of the gearbox. The reliable supply of lubricant to the individual contacts must be ensured for every operating situation.

With the help of Particleworks, it is possible to take a detailed look inside the gearbox under real operating conditions. The influence of different speeds and oil fill levels as well as the influence of lubricant viscosity at different operating temperatures on the wetting of the contacts can be understood much more easily in the simulation model than in real tests.

11.45 – 12.15

Institute of Polymer Processing and Digital Transformation (IPPD), Johannes Kepler University Linz | Dr. Mohammadreza Aali

Assessment of Flight Angle and Rotor Speed Effects on Process Efficiency in Centrifugal Pelletizing Systems: A DEM-MPS-Based Modeling Approach

Centrifugal drying is a key post-processing step in polymer manufacturing, essential for removing residual moisture from pelletized materials. This study employs a coupled Discrete Element Method (DEM) and Moving Particle Simulation (MPS) framework to model particle-fluid interactions within a centrifugal dryer. The influence of rotor speed and flight angle on drying efficiency and power consumption is systematically investigated. Results reveal that flight angle critically affects both moisture separation dynamics and particle transport behavior. A 10° angle minimizes power usage (10.94 kW) but leads to incomplete drying; a 70° angle enhances moisture removal but impairs transport efficiency. An intermediate flight angle of 45° offers the best performance, balancing effective drying and moderate energy use (16.42 kW). Rotor speed also plays a significant role: lower speeds (1280 rpm) reduce energy demand but limit throughput, while higher speeds (1920 rpm) enhance separation but increase power consumption.

Dr. Mohammadreza Aali is a postdoctoral researcher with expertise in polymer processing, computational rheology, and multiphysics modeling, integrating experimental and numerical approaches.

He is currently a university lecturer and senior project scientist at Johannes Kepler University Linz, focusing on advanced simulation techniques for optimizing polymer manufacturing.

12.15 – 13.30

LUNCH

13.30 – 14.00

SPN Schwaben Präzision Fritz Hopf GmbH | Florian Kotz

Simulation of Lubricating Greases in Gear Systems – Challenges, Initial Models, and first Validation

The simulation of lubricating greases in gear systems presents unique challenges due to their complex rheological behavior and limited availability of experimental data. This presentation provides an overview of key issues in numerically modeling grease behavior, particularly within realistic gearbox geometries. A brief introduction to the fundamental rheological properties of lubricating greases and their influence on flow simulations is given. Initial modeling approaches using table-based and power-law methods are presented. These models are then compared with real-world applications. The talk concludes with a look ahead to the next research step: investigating the relationship between NLGI grade and slip condition. The goal is to improve the realism of grease distribution predictions and their impact on gearbox performance.

09.2016 – 05.2019: Vocational training as a mechatronics technician (at SPN)/ A-levels

10.2019 – 02.2023: Bachelor of Engineering in Munich (Dual Form at SPN)

03.2023 – now: Workings as a mechanical Engineer (at SPN)

10.2023 – 07.2025 (planed): Master of Engineering (extra-occupational)

14.00 – 14.30

SKF | Mehul P Pandya - Fabrizio Mandrile

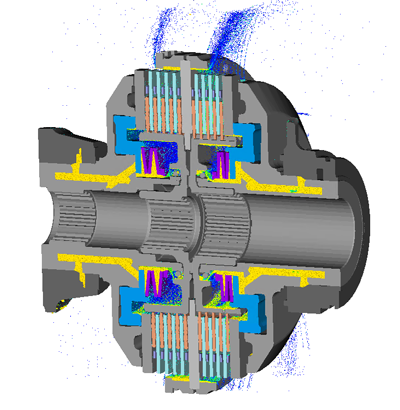

Predicting Bearing Seal Performance: A Particleworks Simulation Study on Water Ingress and Seal Deformation

Seals are critical components in bearings, typically made from rubber, metal, or composite materials. Their primary functions are to prevent contaminants—such as muddy water—from entering the bearing and to retain lubricants, thereby ensuring smooth operation, reducing maintenance costs, and extending the bearing’s service life. Without effective sealing, bearings are prone to rapid lubricant loss and contamination, leading to wear, overheating, and eventual failure.

This study investigates the sealing performance of rubber seals in suspension and wheel-end bearing applications under challenging conditions. Using Particleworks, we simulated two key scenarios:

1. Muddy Water Ingress Test: Evaluates the seal’s ability to prevent muddy water from reaching the ball-set area, protecting steel components like raceways and balls from corrosion and grease degradation.

2. High-Pressure Wash Test: Assesses seal deformation under high-pressure water exposure to ensure that any resulting gap between the seal and housing does not allow water ingress.

To analyze seal deformation, Particleworks was coupled with Ansys, enabling a comprehensive evaluation of how deformation affects water entry into the bearing. These simulations provided valuable insights into sealing performance and supported design optimization across different bearing types and operating conditions.

Additionally, the study explored a novel water breaker concept aimed at further reducing water ingress into the seal cavity. Simulation results were instrumental in comparing various seal designs and validating their effectiveness under real-world conditions.

14.30 – 15.00

DUMAREY & R&D CFD | Anonella Calamiello, Vincenzo Greco, Alfonso Renella – Dumarey Automotive

Pietro Martelli, Matteo Pati, Giuseppe Cicalese – R&D CFD

Characterization of oil flow and thermal behavior of a gearbox for automotive applications

The presentation focuses on an exploratory study of the simulation methodology to study oil splashing within a gearbox for automotive applications, with specific attention to how this affects the thermal fields of the main components. The activity is made of three main parts:

1. Evaluation of oil motion in adiabatic conditions to isolate effects related to local and global particle size on gears and bearings in several operating conditions.

2. Evaluation of oil-air interaction by means of FVM-MPS coupling to assess pros and cons related to a more refined approach.

3. Thermal status of the solid components by means of a steady conjugate heat transfer framework characterized by the testing of several correlations for the evaluation of local heat transfer coefficients.

The numerical results are compared with their experimental counterparts to provide a comprehensive overview of the activity.

Matteo Pati earned his degree in Automotive Engineering from the University of Modena and Reggio Emilia in 2023, working on CFD simulations of two-stroke internal combustion engines. He is currently a CFD analyst in R&D CFD, focusing on meshless and aerothermal calculations.

15.00 – 15.30

BREAK

15.30 – 16.00

R&D CFD | Leonardo Lanciotti, Giuseppe Cicalese

Characterization of the filling process of an internal combustion engine lubricating circuit

The presentation deals with the simulation of the filling process of an interna combustion engine oil circuit. The engine under investigation is part of a generator set which needs to supply energy in the event of a black-out. Hence, it is suddenly switched on straightly at the target operating point to provide the required power in a very few seconds. It is paramount to verify the time to prime the turbines is compliant with reliability requirements.

To this aim, the filling process is simulated and different approaches related to the modelling of very small gaps are compared to draw pros and cons.

Leonardo Lanciotti earned his degree in Automotive Engineering from the University of Modena and Reggio Emilia in 2023, working on CFD simulations of two-stroke internal combustion engines. He is currently a CFD analyst in R&D CFD, focusing on meshless simulations mainly related to lubricating circuits

16.00 – 16.30

SAME DEUTZ FAHR | Tommaso Lucidi - Marco Chiari

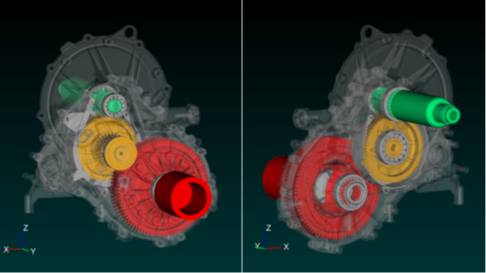

Analysis and Optimization of a PowerShuttle Lubrication Circuit Using Particle-Based CFD

The PowerShuttle is a vital component of agricultural tractor transmissions, enabling smooth directional changes without the need to operate the clutch pedal. It comprises two hydraulically actuated, counter-rotating wet multi-plate clutches: one for forward motion and one for reverse. Proper lubrication of these clutches is essential for ensuring performance, durability and energy efficiency. This study focuses on analysing and optimising the lubrication circuit using Particleworks, which is a particle-based, meshless computational fluid dynamics (CFD) software programme. The analysis aimed to optimise the distribution of the oil flow rate between the two clutches, minimising drag torque while ensuring sufficient lubrication and cooling of both clutch packs. Key simulation results included oil distribution, drag torque levels and local heat transfer coefficients, which were used to evaluate oil film formation and the thermal balance across the clutch disks.

16.30 – 17.00

ZF | Roman Gaspar

Cutting-edge Applications of the Moving Particle Semi-implicit (MPS) Method in Rapid Automotive Development

The Moving Particle Semi-implicit (MPS) method is an advanced numerical approach for simulating fluids and multiphase flows without the need for a computational mesh. In the automotive industry, it finds application particularly in rapid development, where flexibility and simulation speed are crucial. MPS enables realistic modeling of phenomena such as fluid splashing, oil distribution in relatively open space, engine component cooling, or water interaction with vehicle bodies. Thanks to its mesh-free nature and ease to implement CAD, the method is well-suited for simulating complex geometries that often change during early design stages. Integrating MPS into the development cycle shortens the time required for physical testing and reduces prototyping costs. When combined with high-performance computing and parallel processing, it achieves high computational efficiency. The method is becoming a key enabler for innovation in electromobility and aerodynamics. Overall, MPS contributes to accelerating the development of safer, more efficient, and environmentally friendly vehicles.

17.00 – 17.30

DRIVE SYSTEM DESIGN | Michael Bryant and Barry Gladman

Particleworks benchmarking – Assessment of performance for use in the rapid design and development of electrified powertrains

The design and development of electrified powertrains demand simulation tools that deliver both high accuracy and rapid turnaround times. Previously, our design processes relied on another CFD method. However, challenges arose due to prolonged simulation durations and concerns over result fidelity, which impeded iterative design and optimisation efforts.

Transitioning to Particleworks, we conducted a comprehensive benchmarking study to evaluate its performance in simulating oil flow and thermal management within electrified powertrain components. The results were compelling: Particleworks achieved up to a 90% reduction in simulation solve times compared to the previous tool, without compromising on accuracy. This significant improvement facilitated more efficient design iterations, enabling quicker decision-making and enhanced product development cycles.