Smoothed Particle Hydrodynamics and Moving Particle Simulation

Smoothed Particle Hydrodynamics (SPH) and Moving Particle Semi-implicit (MPS) are two particle methods used in fluid dynamics simulation.

SPH is a method used for simulating the mechanics of continuum media. It is a meshfree Lagrangian method, and the resolution of the method can easily be adjusted. This method is used in various fields, like astrophysics, ballistics, volcanology, and oceanography.

On the other hand, MPS is also a meshfree particle method. It was developed to simulate free-surface flows. The method is based on the idea of replacing the pressure terms in the Navier-Stokes equations with a semi-implicit form, which allows for larger time steps and therefore more efficient computation.

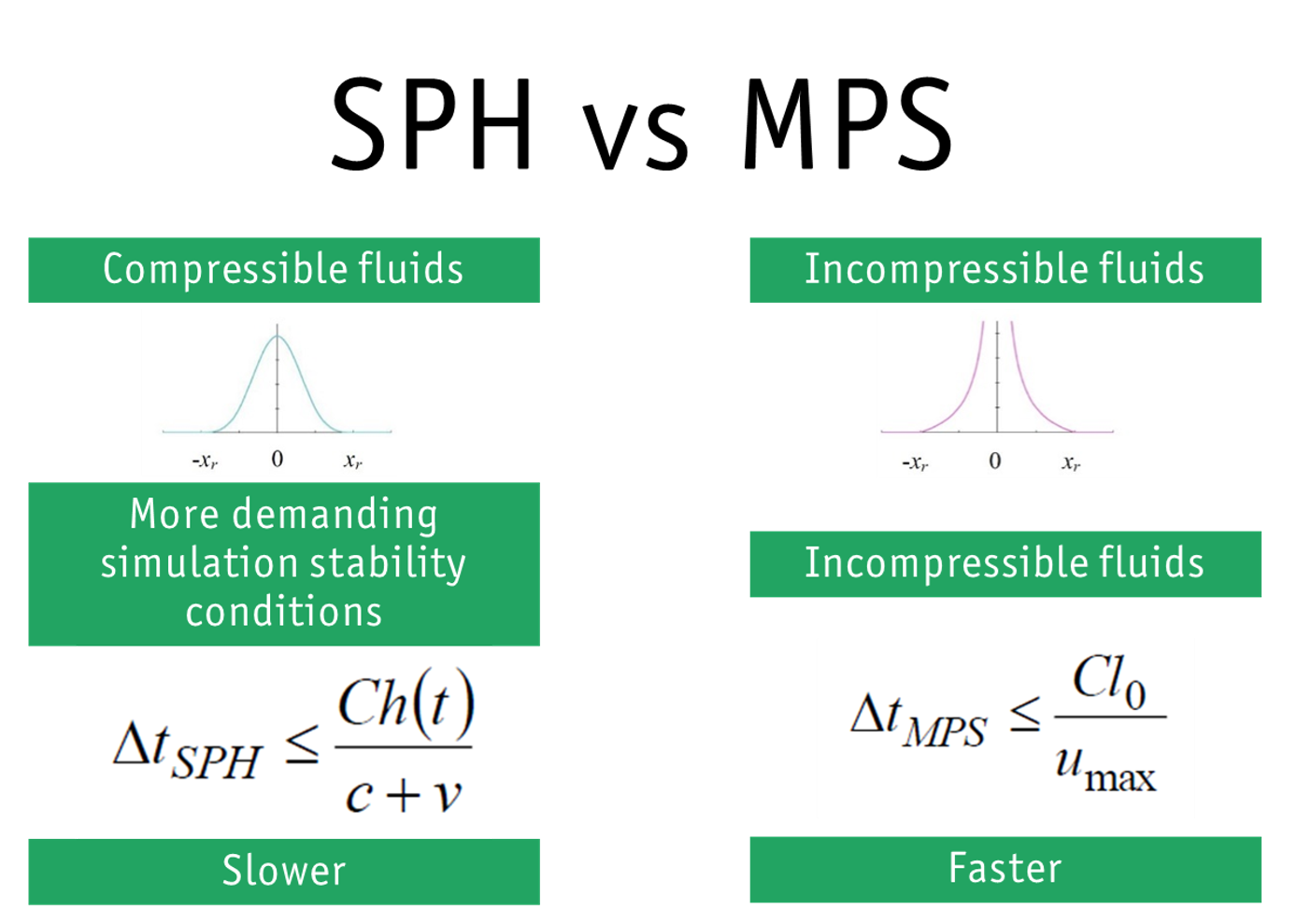

Each method has its own strengths and weaknesses, and the choice of which to use depends on the specific requirements of the simulation.

In more detail, SPH's strength lies in its ability to handle a more physical phenomena, thanks to its comprimibility assumption. However, it can be computationally intensive, which might be a drawback for simulations requiring high efficiency. Moreover, the stability condition when multiphysics is enabled could be more troublesome than MPS.

MPS is highly efficient in computational terms. The incomprimibility assumtption (given the semi-implicit solution of pressure in the Navier-Stokes equations) allows for larger time steps, which in turn leads to faster simulations.

In conclusion, the choice between SPH and MPS methods for fluid dynamics simulation should be dictated by the specific requirements of the physics of the system. Notably, most of the the sectors where free surface flow is predominant have low velocities field, i.e. low Mach numbers and incompressible fluid.

Thus, when simulating bearings lubrication, gearbox splashing and cooling, oil jets in e-motors and mixing of highly viscous fluids, Moving Particle Simulation is preferred than Smoothed Particle Simulation for faster, simpler and more stable results.