CUTTING TOOLS

In the realm of CNC and machining, the cooling of cutting tools is a pivotal aspect. The increasing demands of precision and efficiency in industries have rendered traditional coolant methods inadequate. This has led to the emergence of an innovative solution: high-pressure coolant systems. There are several challenges associated with the management of coolant in cutting tools. It’s vital to control tool temperatures to avoid overheating and ensure durability. Identifying temperature hotspots is a key factor in preventing tool failure. Other issues include the disruption of the machining process and increased tool wear due to non-uniform cooling or contamination.

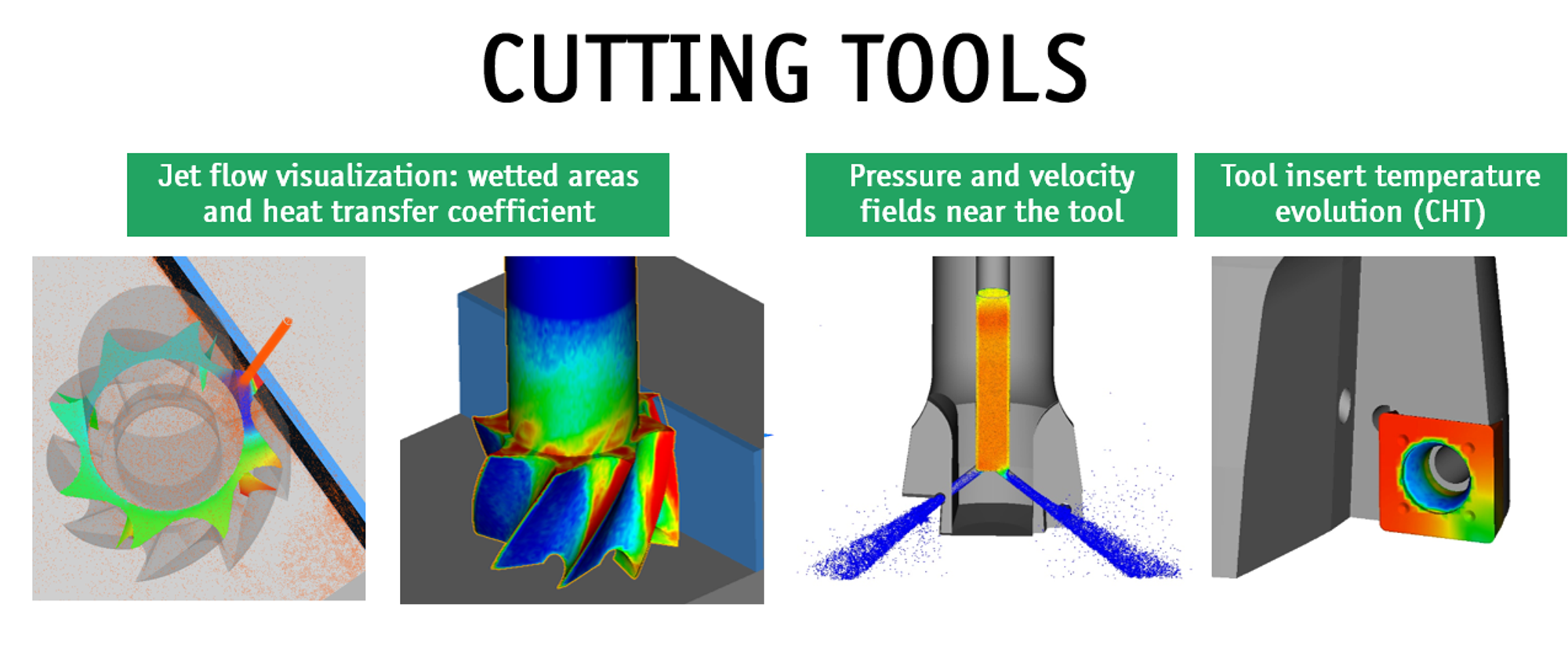

Particleworks creates digital prototypes of tools for drilling and other CNC machining processes:

- Oil emulsion distribution and accumulation around the tool

- Pressure drops in internal channel at given flowrate-RPM condition

- Temperature evolution of insert

- Wetted and cooled areas on the tool