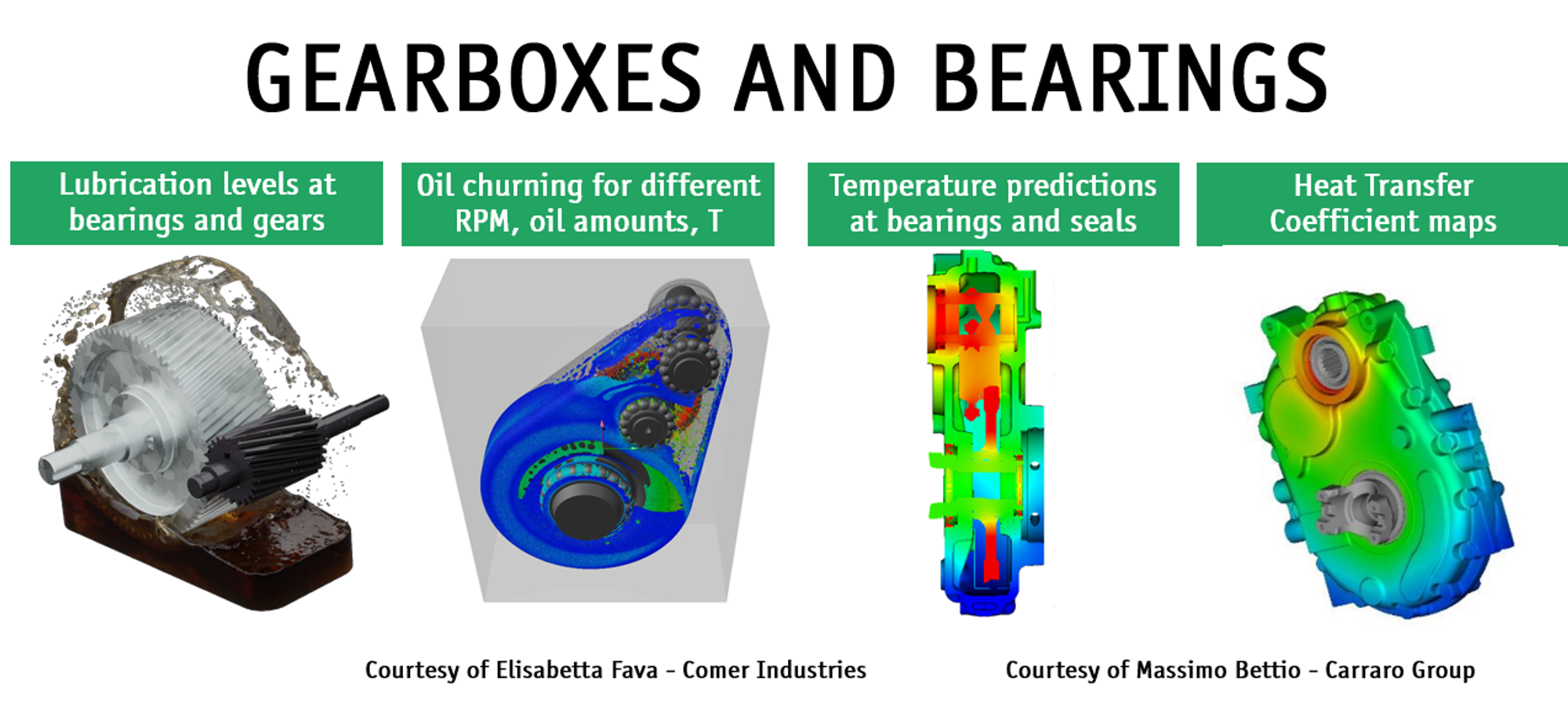

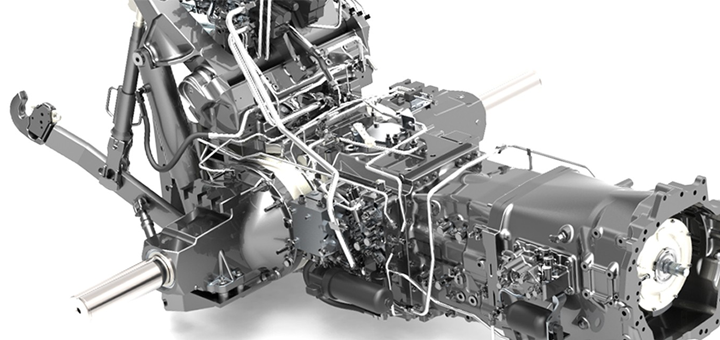

GEARBOXES AND BEARINGS

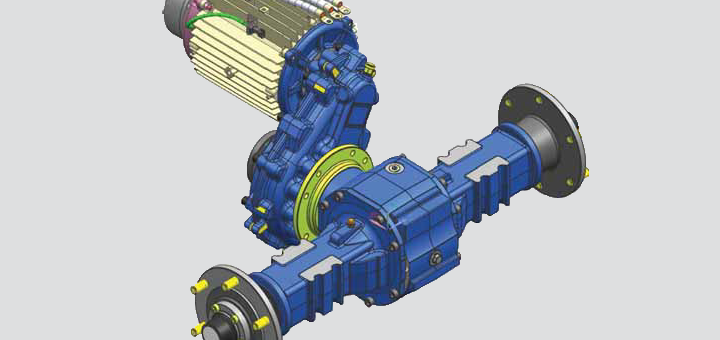

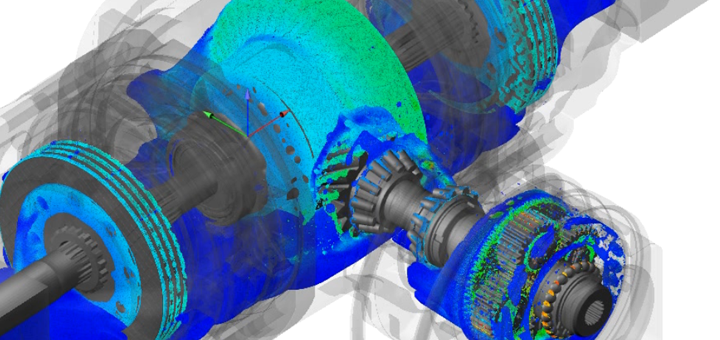

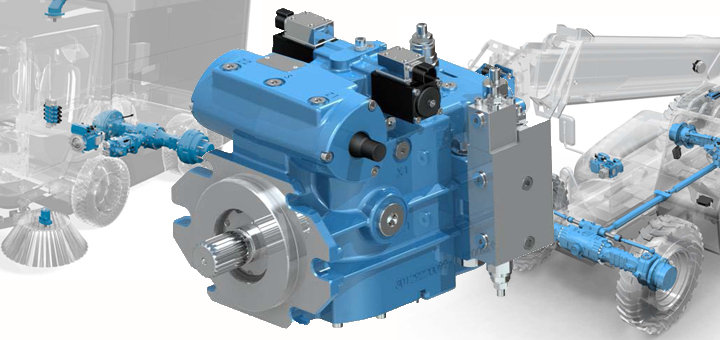

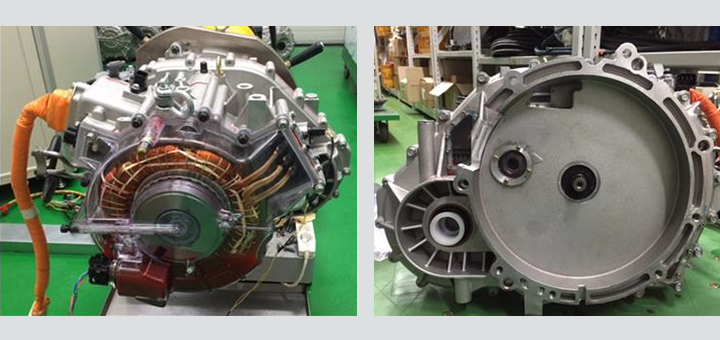

Designing gearboxes and transmissions involves managing complex challenges. A key aspect is simulating oil sloshing, which affects system performance and reliability. Abrupt maneuvers can cause inconsistent lubrication, overheating, and mechanical failure. This simulation also aids in designing effective oil management systems. Additionally, bearing lubrication is crucial to reduce friction and wear. However, it can lead to churning losses, reducing overall efficiency. Furthermore, the pump’s air intake must be carefully managed to prevent cavitation, ensuring optimal operation. These factors make this field a complex and fascinating area of engineering.

Particleworks creates digital prototypes of transmission, powertrain and gearboxes to investigate:

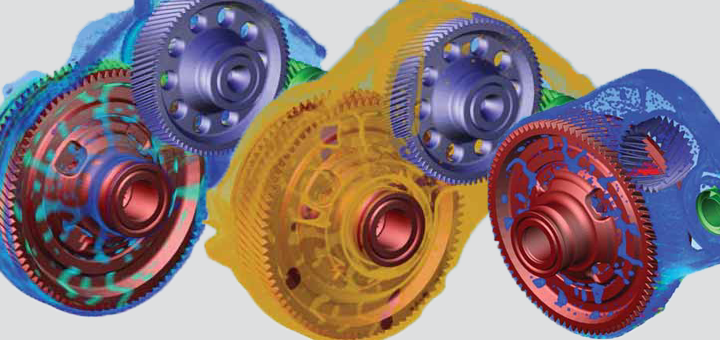

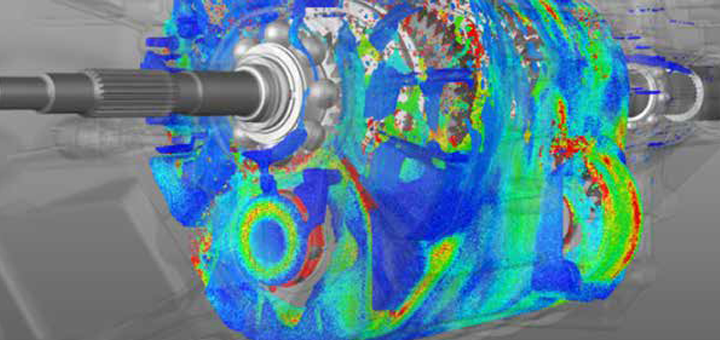

- Churning losses attributed to oil

- Flow analysis and baffle design for enhanced oil distribution

- Oil intake reliability in pumping areas (and minimizing air intake)

- Heat Transfer Coefficient in relation to fluid phase

- Wetted and lubricated areas

- Oil aeration and its effects on lubrication

- Operating temperatures of gearbox for different load condition