STERILIZATION, FOOD AND CONSUMER GOODS

In the engineering of sterilization processes for food and consumer goods, managing complex variables is crucial. Key to this is modeling the thermal or chemical inactivation of pathogens, impacting product safety and longevity. Thermal gradients or inconsistent agent distribution can lead to partial sterilization, increasing the risk of product failure. Simulations assist in optimizing sterilization cycles for effectiveness and efficiency. Ensuring deep penetration of sterilizing agents while maintaining product integrity requires precise control, yet overuse can compromise quality, affecting consumer acceptance. Also, air removal from the sterilization environment is vital to eliminate cold spots and achieve uniform treatment. These technical challenges underscore the intricate and critical nature of sterilization process engineering.

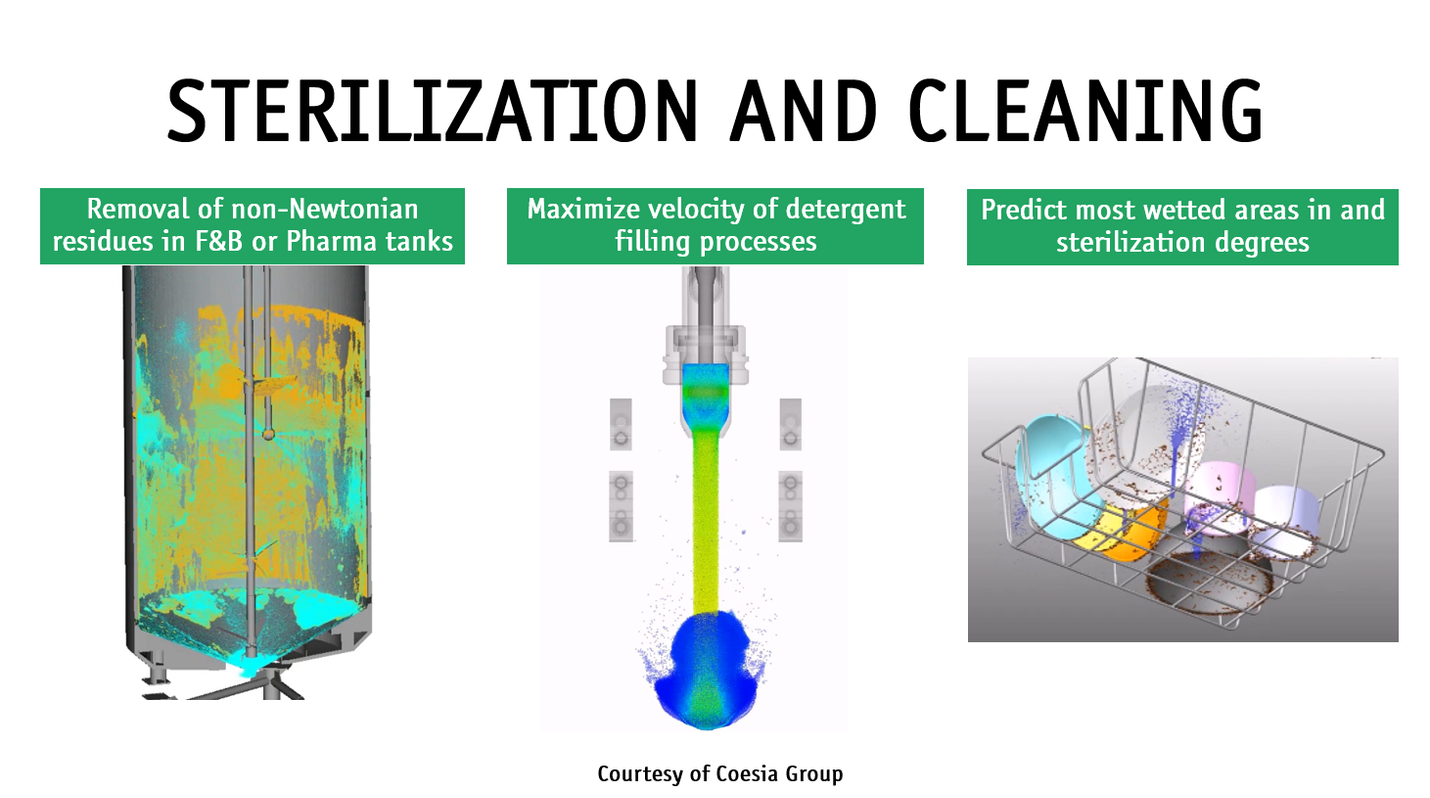

Particleworks creates digital prototypes and simulation of dishwashers, cleaning in place systems and food feeding machines to investigate:

- Improved cleaning jets directionality (i.e. dishwashers)

- Scraping of non-Newtonian process residues

- Visualize sterilized surfaces of food and beverage packaging

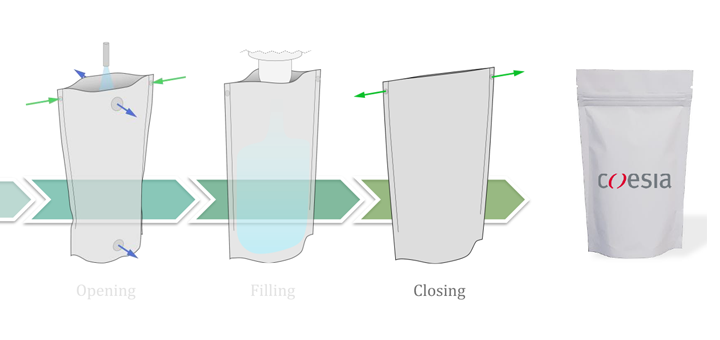

- Speed up filling of bottles and flexible pouches

- Evaluate deformation on packaging due to fluid phase

- Improve flow of multi-phase (i.e. soups and other fluid-solid mixtures)